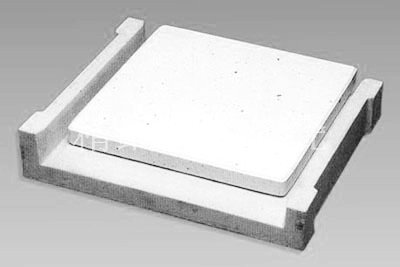

Mullite push plate Description:

Corundum mullite push plate (moved into the board), corundum mullite sagger, corundum mullite corrugated boards, pillars and other corundum mullite kiln furniture, aluminum oxide content greater than 90%, mainly corundum crystal phase refractory products, has a high compressive strength at room temperature (up to 340MPa), high load softening start temperature (greater than 1800 ℃). Good chemical stability, acid or alkaline slag, metal and glass fluid, etc. have a strong ability to resist high refractoriness, good thermal shock resistance (resistance temperature acute degeneration), high-temperature strength, resistance to slag penetration strong expansion coefficient, low creep, do not slag off, easy to crack, with stability, is the ideal tool for high-temperature kiln, adapt to various conditions of high temperature furnace atmosphere used; widely used 95,99 alumina ceramic and zirconia ceramic and fluorescent materials, powder metallurgy, electronic ceramics, magnetic materials, high-temperature sintering ceramic powder.