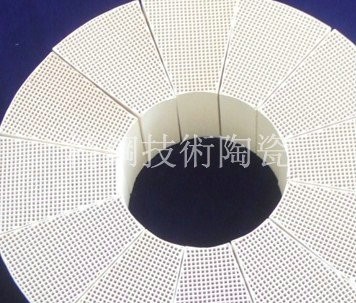

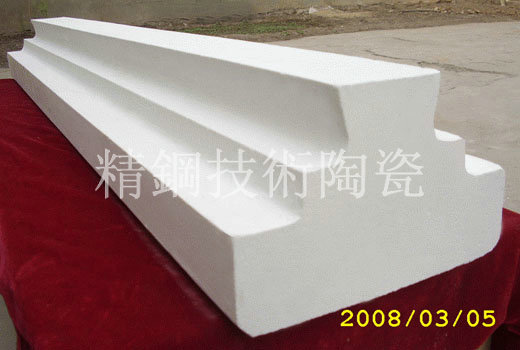

Corundum refractory bricks are imported new technology, using high-purity mullite clinker, depending on the temperature, adding aluminum chloride burn filler made of composite products, high temperature sintering, direct synthesis of mullite phase energy materials can be exposed to direct flame. Currently used by the relevant units, the product of similar foreign products, a variety of technical indicators. Advanced furnace must use novel materials, novel materials is high mullite insulating refractories.

[Features]

High purity, low impurity content;

High temperature, direct contact with the flame, resistance to various corrosive atmosphere;

Low thermal conductivity, low melt;

High strength and has excellent thermal shock resistance;

Size, high precision, can be arbitrarily cut.

【Usage】

Ceramic roller kiln, tunnel kiln, shuttle kiln, Bell kiln, various resistance furnace;

Chemical industrial furnace, cracking furnace, conversion furnace, gas furnace;

Metallurgical industrial furnace, stove, furnace, soaking furnace, heat treatment furnace;

Industrial furnace hot face refractory lining and other refractory insulation backing.